Laser cutting solutions Provider

On Demand Customization Process intelligence

On Demand Customization Process intelligence

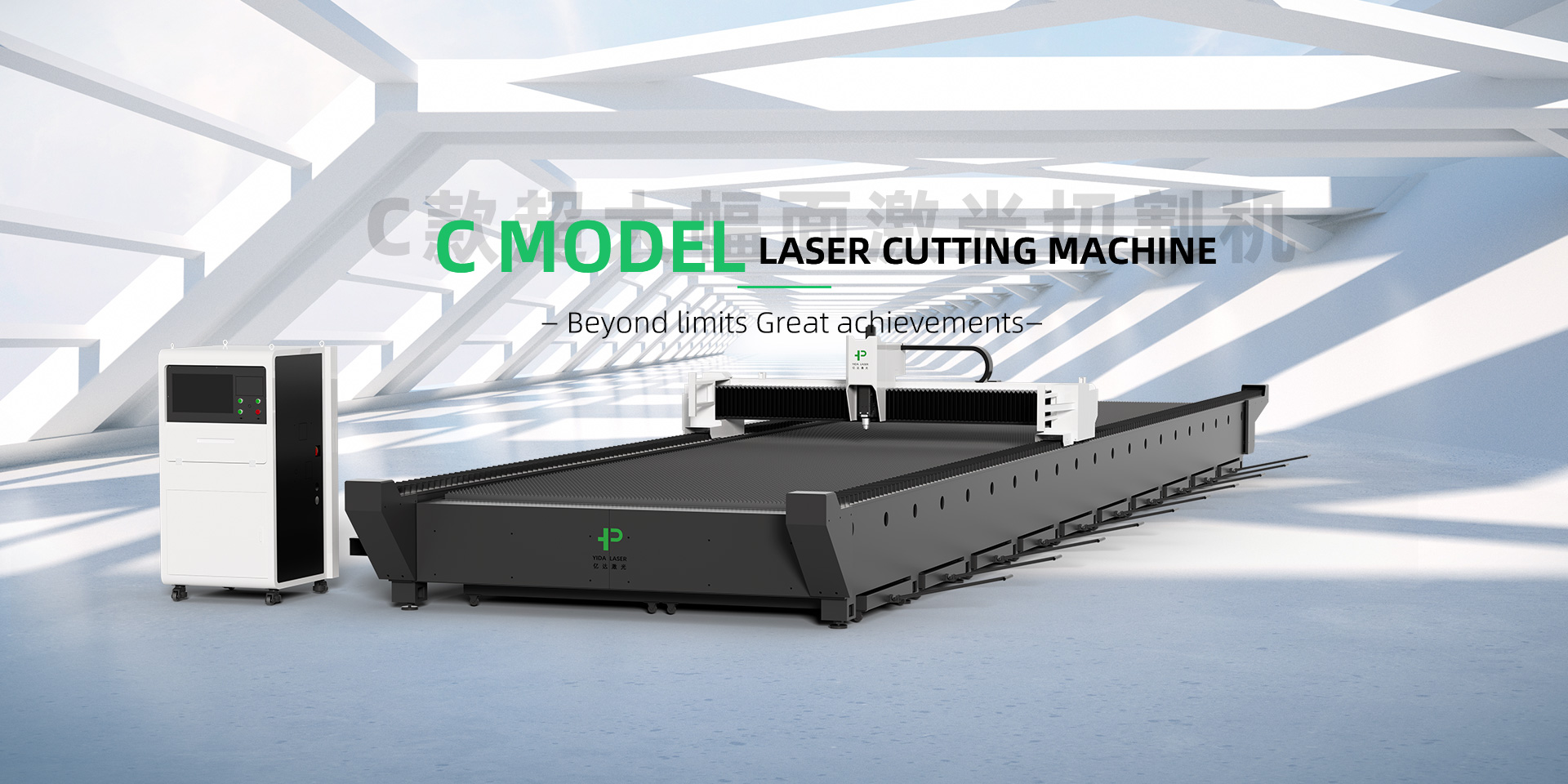

Professional laser cutting software, Special design Fully-enclosed body with exchange platform,

Full aspects monitoring system to ensure safe and stable during laser cutting process,

high-rigid and solid cast iron body, minimum structure deformation,

super low vibration, precise and high accuracy.

Gantry structure design, linear drive with rack and pinion,

Stable structural, high rigidity, high speed travel.

Innovative Table Exchange Technology, improved works efficiency;

Solid Welded Machine body,

provide stability during table exchanging process

Solid Machine structure welded together with

iron frame and cast aluminum beam.

Single platform system,

simple and easy to operate,

also having high positioning accuracy.

For more environmental friendly, as optional,

customer can consider to add on the accessories

like dust collector.

The large format machine allow more different sizes,

types and thickness of material to be placed on the table at the same time in order to reduce the plate loading time.

Intelligent control system work perfectly to improve the machine operation and cutting efficiency.

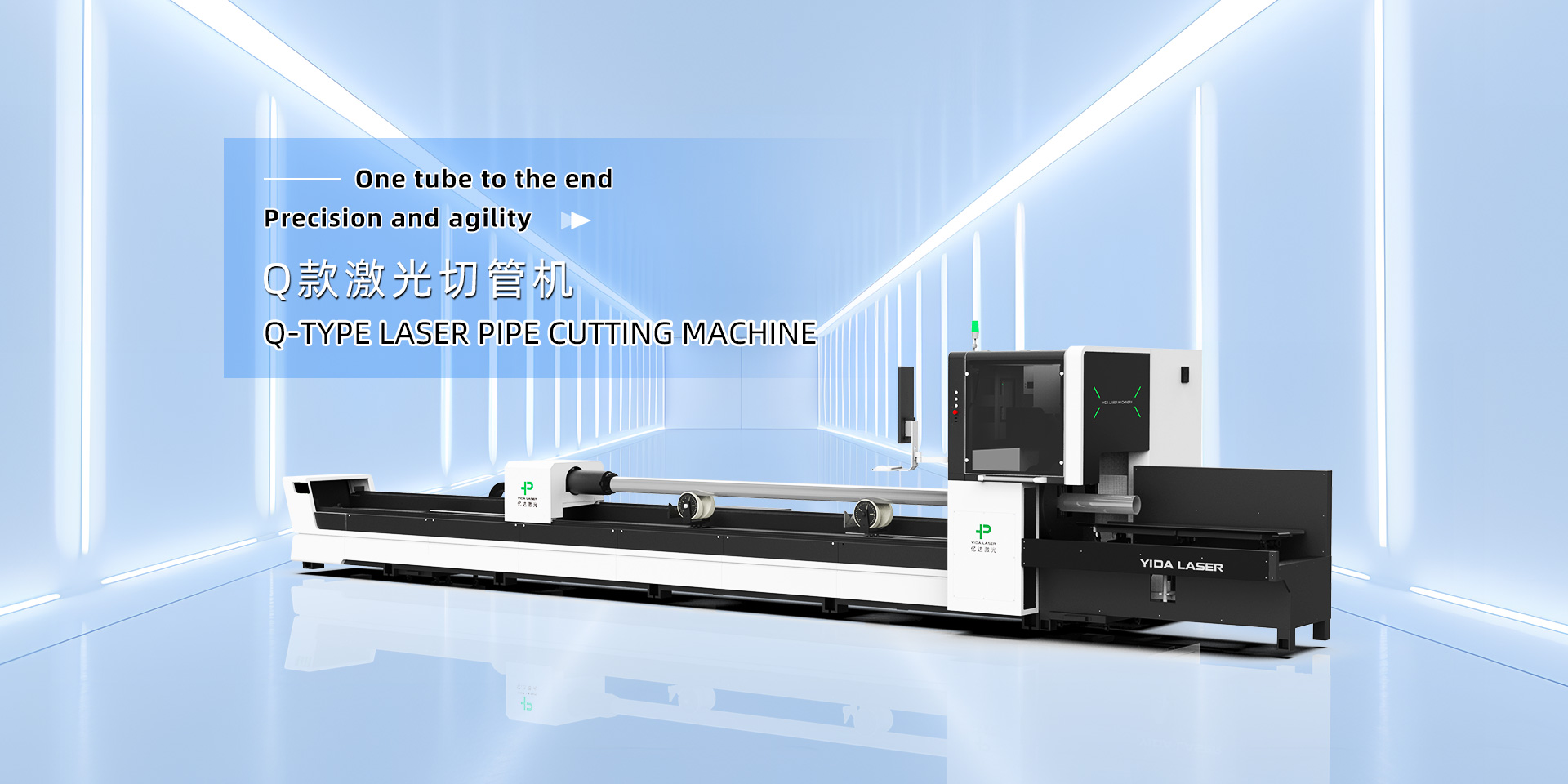

High precision chuck to hold the pipe position,

the chuck movement control by synchronization of servo motor and belt.

A comprehensive operating system, special designed and suitable for all kinds of tube cutting.

Laser plate cutting machine, laser cutting machine,

YD laser AG series coil fed laser cutting machine,

casting bed body, specialize for coil processing .

The fixation of pipes adopts high-precision chuck clamping, which is achieved through the transmission method of servo motor synchronous belt. The specialized system and integrated operation process are suitable for diversified cutting of various pipes.

Learn moreThe Tower provides capabilities for auto loading and unloading of raw materials and finished parts,

to create a productive and flexible manufacturing environment.

The Tower provides capabilities for auto loading and unloading of raw materials and finished parts,

to create a productive and flexible manufacturing environment.